Endura Hi-Tech Wrap construction V belts :

Endura Hi-Tech 'CORE' V belts are endless belts used for a wide range of applications providing a technically and economically good design for most ordinary drives. They are antistatic, oil and heat resistant and can be used in application where belt linear speed do not exceeds 45metres/sec.

Our Endura Hi-Tech “Core” belts are having a rounded Top surface, as against the flat surface of competitors. The convexly curved top surface absorbs the tensioning force which acts perpendicular to the top & prevents the deformation of the shape. It makes the belt to seat properly into the pulley groove and prevents excessive wearing. Resulting in optimum power transmission and enhances the belt life.

Feautres

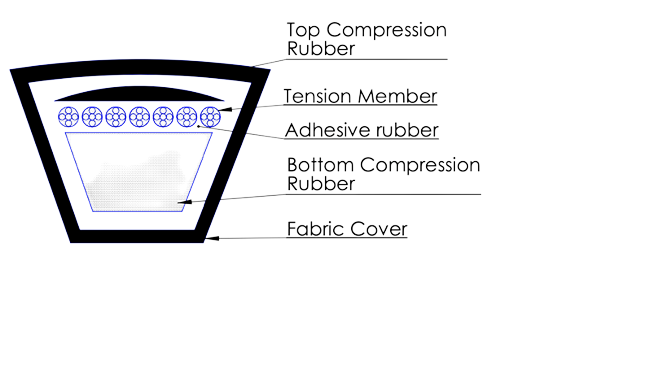

Cover fabrics enhance durability by protecting inner parts.

Specially designed cords enhance durability and length stability.

Excellent in resistance against heat, ozone, sunlight, weather, and aging. • Safe use is ensured by preventing static electricity.

Enhances power transmission efficiency by reducing slip .

Chloroprene rubberized wrapping fabric resists abrasion.

Made from high performance polymers for smooth transfer of power.